Precision Woven Synthetic Filter Mesh

What is Precision Woven Filter Mesh

It is a synthetic woven filter mesh made of monofilament yarn, specialized in defined and controlled, consistent and repeatable material properties such as mesh opening (pore size), fabric/mesh thickness, tensile strength, dimensional stability, cleanliness and so on.

Advantages of Precision Woven Filter Mesh

- Yarn Diameter and evenness are carefully controlled to ensure high level from lot-to-lot

- Openings are controlled to tight tolerance and aperture control is inherent to manufacturing process

- Mesh Surface properties are even and consistent

- Thickness tolerance is within microns through entire rolls and lots

- Cleanliness meets rigid and strict standards

- Consistence is well-governed for each lot

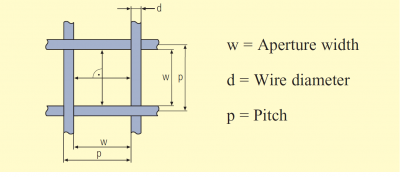

Open Mesh Terminology

Aperture width w is the distance between two adjacent

warp or weft wires.

Wire diameter d is the diameter of the wire in the woven

mesh.

Pitch p is the distance between the middle point of two

adjacent wires or the sum of the aperture width w and the

wire diameter d.

Warp: All wires running lengthwise of the cloth as woven.

Weft: All wires running across the cloth as woven.

Open Area, Ao: The percentage of the area of

all the apertures in the total screening surface

Ao = 100 . (w : p)2

Type of weave is the way in which the warp and weft

wires cross each other.

The number of apertures per unit length n is the number

of apertures which are counted in a row one behind the

other for a given unit length. The unit length may be 1 cm,

1 inch or any other unit of length. (The number of

apertures with a length of 24.5 mm is designated as

“Mesh”.)

Mesh = number of apertures per English inch = 25.4 : p

n/cm = number of apertures per cm = 10 : p

n/cm2 = number of apertures per cm2 = (10 : p)2