Company Blog

Products for Filtration, Separation, Sifting and Printing

Polymer Knowledge Series: Comprehensive Guide on ABS (Acrylonitrile Butadiene Styrene)

- Font size: Larger Smaller

- Hits: 3932

- Subscribe to this entry

- Bookmark

Polymer Knowledge Series---Acrylonitrile Butadiene Styrene (ABS)

Comprehensive Guide on ABS

Acrylonitrile Butadiene Styrene, often abbreviated as ABS, is an opaque engineering thermoplastic widely used in electronic housings, auto parts, consumer products, pipe fittings, lego toys and many more. Get detailed technical information about ABS polymer and know more about its key properties, limitations, applications, processing conditions and much more.

ABS – What does it stand for?

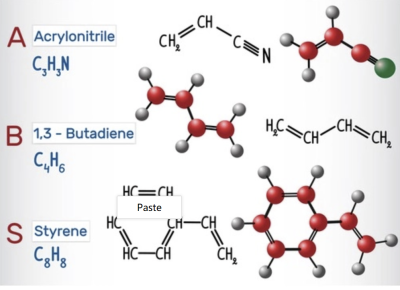

ABS stands for Acrylonitrile Butadiene Styrene. ABS is an impact-resistant engineering thermoplastic & amorphous polymer. ABS is made up of three monomers: acrylonitrile, butadiene and styrene:

- Acrylonitrile: It is a synthetic monomer produced from propylene and ammonia. This component contributes to ABS chemical resistance & heat stability

- Butadiene: It is produced as a by-product of ethylene production from steam crackers. This component delivers toughness & impact strength to ABS polymer

- Styrene: It is manufactured by dehydrogenation of ethyl benzene. It provides rigidity & processability to ABS plastic

How ABS is Made?

ABS is produced by emulsion or continuous mass technique. The chemical formula of Acrylonitrile Butadiene Styrene is (C8H8·C4H6·C3H3N)n. The natural material is an opaque ivory color and is readily colored with pigments or dyes.

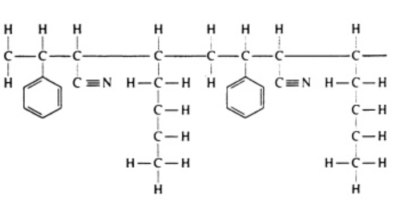

Molecular Structure of Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene has a broad processing window and can be processed on most standard machinery. It can be injection-molded, blow-molded, or extruded. It has a low melting temperature making it particularly suitable for processing by 3D printing on an FDM machine.

ABS falls between standard resins (PVC, polyethylene, polystyrene, and so on) and engineering resins (acrylic, nylon acetal…) and often meets the property requirements at a reasonable price-cost effectiveness.

Key Properties of ABS

ABS is an ideal material of choice for various structural applications, thanks to its several physical properties such as:- High rigidity

- Good impact resistance, even at low temperatures

- Good insulating properties

- Good weldability

- Good abrasion and strain resistance

- High dimensional stability (Mechanically strong and stable over time)

- High surface brightness and excellent surface aspect

Chemical Properties of ABS

- Very good resistance to diluted acid and alkalis

- Moderate resistance to aliphatic hydrocarbons

- Poor resistance to aromatic hydrocarbons, halogenated hydrocarbons and alcohols

Mechanical Properties of ABS

| Elongation at Break | 10 - 50 % |

| Elongation at Yield | 1.7 - 6 % |

| Flexibility (Flexural Modulus) | 1.6 - 2.4 GPa |

| Hardness Shore D | 100 |

| Stiffness (Flexural Modulus) | 1.6 - 2.4 GPa |

| Strength at Break (Tensile) | 29.8 - 43 MPa |

| Strength at Yield (Tensile) | 29.6 - 48 MPa |

| Toughness (Notched Izod Impact at Room Temperature) | 200 - 215 J/m |

| Toughness at Low Temperature (Notched Izod Impact at Low Temperature) | 20 - 160 J/m |

| Young Modulus | 1.79 - 3.2 GPa |

Electrical Properties of ABS

| Arc Resistance | 60 - 120 sec |

| Dielectric Constant | 2.7 - 3.2 |

| Dielectric Strength | 15.7 - 34 kV/mm |

| Dissipation Factor | 50 - 190 x 10-4 |

| Volume Resistivity | 14 - 16 x 1015 Ohm.cm |

ABS is readily modified both by the addition of additives and by variation of the ratio of the three monomers Acrylonitrile, Butadiene and Styrene. Heat stabilizers, hydrolysis stabilizers, lubricants, UV stabilizers etc. are being used in non-reinforced and reinforced grades to increase specific material properties.

Hence, grades available include:

- High and medium impact

- High heat resistance, and

- Electroplatable

Limitations of ABS

- Poor weathering resistance

- Ordinary grades burn easily and continue to burn once the flame is removed

- Scratches easily

- Poor solvent resistance, particularly aromatic, ketones and esters

- Can suffer from stress cracking in the presence of some greases

- Low dielectric strength

- Low continuous service temperature

ABS Blends – Thermoplastic Alloy

To overcome some of these limitations, ABS can be readily blended or alloyed with other polymers such as PA, PBT, PC etc. This blending with polymers further increases the range of properties available such as mechanical, thermal... & more. Get instant access commercially available ABS/thermoplastics blends using the link below:Now, let’s discuss ABS/PC blend in detail...

ABS/PC is an abbreviated form used for acrylonitrile butadiene styrene/polycarbonate blend. It is a thermoplastic alloy made up of polycarbonate and acrylonitrile butadiene styrene. Both of these polymers are widely used on their own and have very specific properties and also drawbacks of their own.

However, when alloyed together they form one of the most widely used industrial amorphous thermoplastics with:

- Enhanced processability

- Good flow characteristics, strength, stiffness and,

- Good heat resistivity

Furthermore, additives can be added in the blend to improve for example its UV and oxidation stability, fire safety and reinforcing agents such as glass fibers and mineral fillers are added to improve the blend's strength and rigidity.

Acrylonitrile Butadiene Styrene/Polycarbonate (ABS/PC) blends are commonly used in commercial and industrial applications such as example automotive, electronics, telecommunication, etc. where hard yet light-weight, heat resistant and easily processed materials are required.

ABS Processing Conditions

Acrylonitrile-butadiene Styrene (ABS) has a broad processing window and can be processed on most standard machinery.- Injection Molding

- Pre-drying is not always needed for injection molding with a vented cylinder. In case drying is needed then 4 hours at 80°C is generally sufficient. Signs of moisture are stripes, streaks or bubbles in the molding and if any of these are seen then the material should be pre-dried

- Melt temperature: 210-270°C

- Mold temperature: of 40-70°C

- Material Injection Pressure: 50 - 100 MPa

- Injection Speed: Moderate - High

- Extrusion

- Pre-Drying: 3 hours at 70-80°C

- Extrusion temperature: 210 to 240°C

- Screw Design: L/D ratio of 25-30 is recommended

Last modified on