Company Blog

Products for Filtration, Separation, Sifting and Printing

Why we choose polyamide or nylon filter mesh for filtration? here it goes

- Font size: Larger Smaller

- Hits: 5376

- Subscribe to this entry

- Bookmark

Poly-amide or Nylon Filter Mesh is made by weaving yarns in plain and twill style, working as surface filter material to retain particles from fluid/oil/liquid. As nylon filter mesh is woven with yarns, there are spacing between two adjacent yarns, which is aperture. The spacing between two adjacent yarns, we call it " aperture" or "mesh opening", in filtration, it is name "micron rating".

Micron rating measures the efficiency of filter material when feed passes through filter material where particles suspended in the fluid/liquid, bigger than the mesh holes, will be captured onto the mesh surface, filtered fluid will pass through the filter mesh without these unwanted particles/solids, which we call "filtrate".

However, nylon filter mesh works as "surface filtration", which is nominal filtration, not absolute filtration, which indicates that some particles unwanted will still pass through the filter meshes into the filtrate. As the filter cake is formed, filtration rate will increase which will traps more particles and let less unwanted particles slip through the mesh holes.

When nylon filter mesh is introduced as filter material, and we will need to understand some parameters, because we need to select proper filter meshes, without knowing these, we will get lost when facing a variety of filter mesh in front of us, below are some

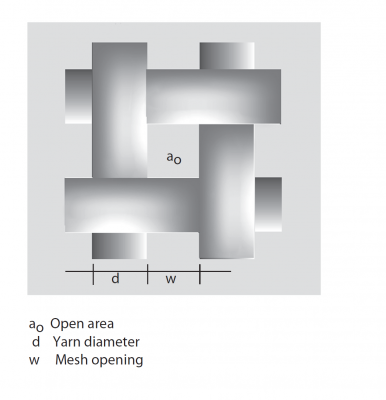

Mesh Count: This noun is used to describe the numbers of yarns in specific area, usually in one centimetre or in one inch.

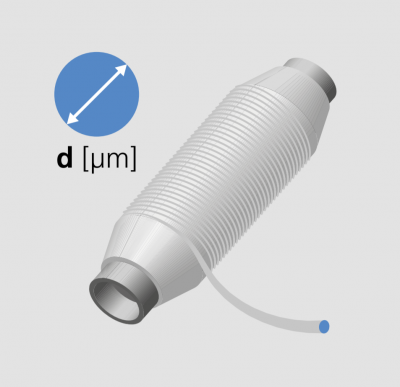

Thread Diameter: literally speaking, it is the diameter of yarn to be woven

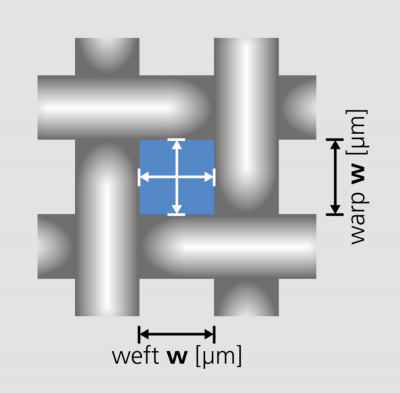

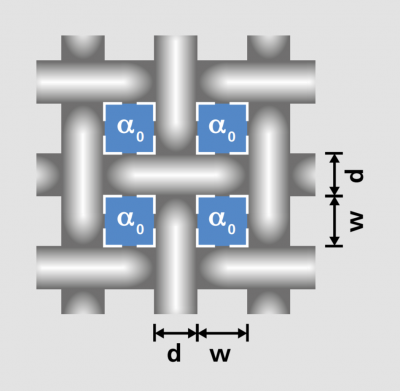

Mesh Opening: Spacing between two adjacent yarns in both weft and warp directions, which is the major parameter when referring to the micron rating or filter efficiency.

Open Area: which is expressed in percentage, meaning holes numbers in specific area, the bigger open area is, the better filtration efficiency will be when thread diameter or mesh count is fixed

.

The reason why polyamide or nylon filter mesh is used more often than polyester in filtration needs.

To explain the reason of this, we will need to understand the basic properties of PA6 or PA6.6 (two most important polyamide synthetic used in weaving filter meshes), and then we will understand why they are used more often.

Properties of PA6 and PA6.6:

- High strength and stiffness at high temperature

- Good impact strength, even at low temperature

- Very good flow for easy processing

- Good abrasion and wear resistance

- Excellent fuel and oil resistance

- Good fatigue resistance

- PA 6 has excellent surface appearance and better processability than PA66 (due to its very low viscosity)

- Good electrical insulating properties

- High water absorption and water equilibrium content limits the usage

- Low dimensional stability

- Attacked by strong mineral acids and absorbs polar solvents

- Proper drying before processing is needed