Introduction:

Nylon Screen Printing Mesh is a polyamide mesh, better known to the rest of the world as nylon. Nylon meshes are the oldest monofilament chemical fiber meshes used for industrial screen printing. The key characteristics of nylon are mechanical resistance, excellent elasticity and very good ink flow. These properties make nylon printing mesh an excellent choice for

applications that involve the use of highly abrasive inks (such as ceramic inks) and applications where the mesh needs to perform and adapt to the shape of the substrate (3D objects).

Features:

• Standard polyamide mesh

• High abrasion resistance

• High printing performance on 3D objects

• Very good ink flow properties

Applications:

The principal application for Nylon Screen Printing is printing solid objects that have 3-D qualities. These applications typically use mesh specifications that are 77 threads per inch and higher, and include products such as bottles, containers and advertising promotional materials. However,Nylon Screen Printing Mesh is also an excellent option when printing ceramic tiles and decals to be used on ceramic and glass. For any of these applications, the elasticity of Nylon Screen Printing Mesh is especially high, which enables excellent printing results—even on the most difficult surfaces

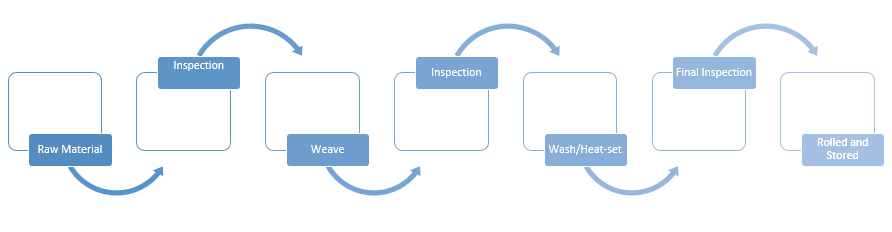

Production Procedure:

|

Fabric Number |

Mesh count |

Thread Diameter |

Mesh Opening |

Open Area |

Fabric Thickness |

Weight |

|

|

No. |

cm mesh/inch |

micron |

micron |

% |

micron |

g/m2 |

|

|

JPP5 |

5 |

12 |

500 |

1500 |

56 |

850 |

271 |

|

JPP6 |

6 |

16 |

400 |

1267 |

58 |

780 |

208 |

|

JPP7 |

7 |

18 |

350 |

1079 |

57 |

675 |

186 |

|

JPP8 |

8 |

20 |

350 |

900 |

52 |

685 |

212 |

|

JPP9 |

9 |

24 |

250 |

860 |

60 |

455 |

145 |

|

JPP10 |

10 |

25 |

300 |

700 |

49 |

576 |

195 |

|

JPP12 |

12 |

30 |

250 |

583 |

49 |

470 |

162 |

|

JPP12 |

12 |

35 |

300 |

533 |

41 |

585 |

234 |

|

JPP14 |

14 |

40 |

300 |

414 |

34 |

595 |

273 |

|

JPP16 |

16 |

40 |

200 |

425 |

46 |

370 |

139 |

|

JPP16 |

16 |

50 |

250 |

375 |

36 |

485 |

217 |

|

JPP20 |

20 |

50 |

150 |

350 |

49 |

375 |

98 |

|

JPP20 |

20 |

50 |

200 |

300 |

36 |

385 |

173 |

|

JPP24 |

24 |

60 |

150 |

267 |

41 |

285 |

117 |

|

JPP28 |

28 |

70 |

120 |

237 |

44 |

215 |

87 |

|

JPP30 |

30 |

76 |

120 |

213 |

41 |

225 |

94 |

|

JPP32 |

32 |

80 |

100 |

213 |

46 |

165 |

69 |

|

JPP36 |

36 |

90 |

100 |

178 |

41 |

178 |

78 |

|

JPP40 |

40 |

100 |

100 |

150 |

36 |

190 |

87 |

|

JPP43 |

43 |

110 |

80 |

152 |

43 |

135 |

60 |

|

JPP48 |

48 |

120 |

80 |

130 |

38 |

145 |

62 |

|

JPP56 |

56 |

140 |

60 |

120 |

44 |

85 |

44 |

|

JPP59 |

59 |

150 |

60 |

110 |

42 |

98 |

46 |

|

JPP64 |

64 |

160 |

60 |

100 |

37 |

105 |

50 |

|

JPP72 |

72 |

180 |

50 |

90 |

41 |

82 |

39 |

|

JPP80 |

80 |

200 |

50 |

75 |

36 |

90 |

43 |

|

JPP100 |

100 |

250 |

40 |

60 |

36 |

65 |

35 |

|

JPP120 |

120 |

305 |

40 |

43 |

25 |

70 |

42 |

|

JPP130 |

130 |

330 |

40 |

37 |

23 |

75 |

45 |