In industrial filtration field, more and more molded filters are applied thanks to the development of injection molding technology and fabrication techniques used to make mesh filter components.

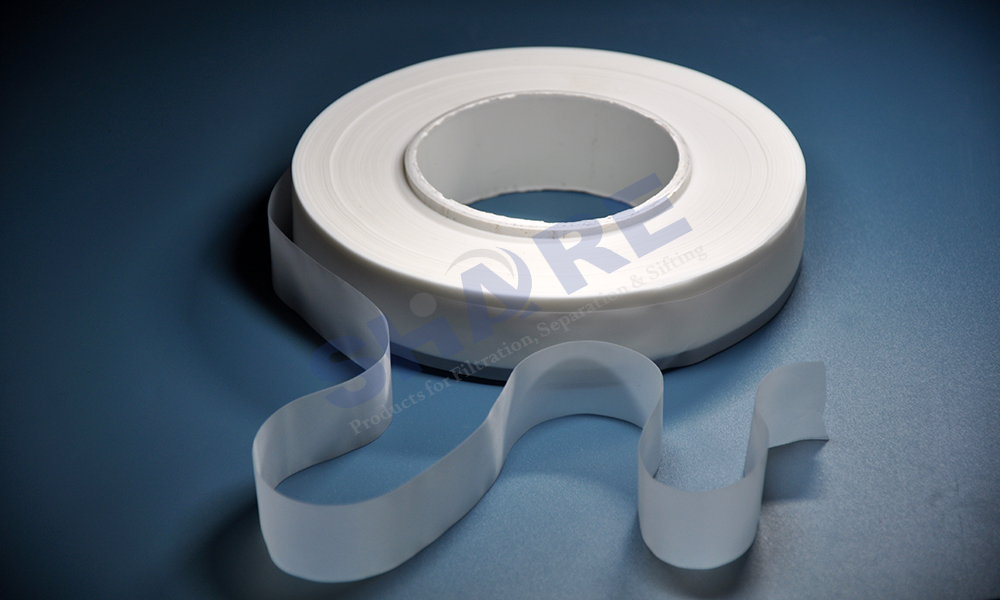

Raw filter meshes can be further fabricated into different styles and shapes, such as mesh filter ribbons, filter bags, filter tubes, filter discs, special filter pieces..., these filters are manufactured and converted by ultrasonic, heat cutting, slitting, cold punching/slitting, ultrasonic pleating.

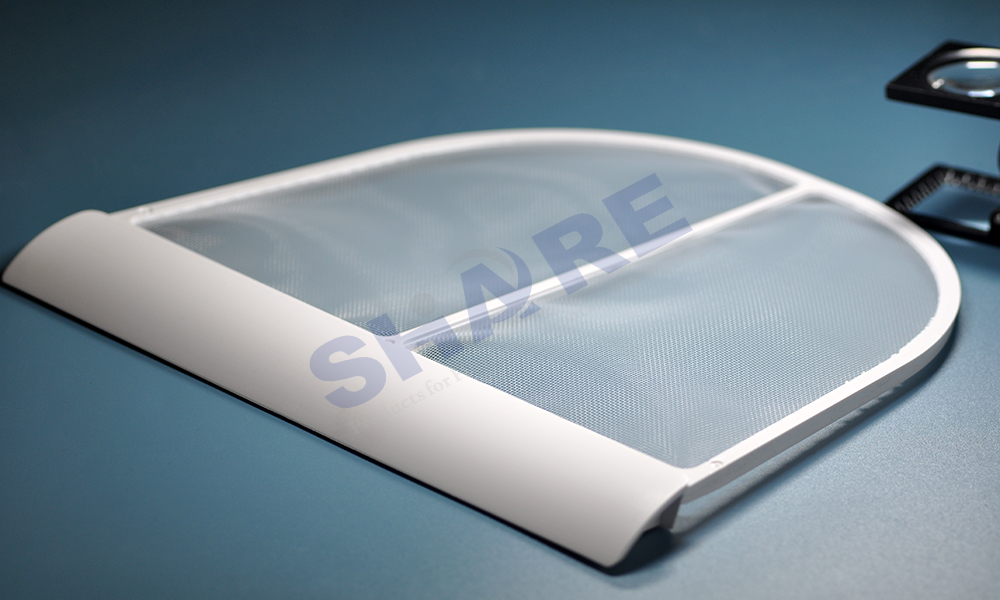

In home appliance, automotive, irrigation, medical, food and beverage,... industries, molded plastic filters are needed. Mesh filters are molded by injection machine, purely mesh is soft and in these industries, rigid and strong frame are required to support the filter meshes for filtration application, then injection molding is introduced, this production technique can cover the filter mesh with different plastic resins, such as ABS, POM, PP, PA6 series, PC, PE and other plastic resins as well as silicone, rubber material.